| |

|

|

| |

| |

|

| March 2007 |

Honmono in action

- Honmono Story 2 |

|

|

This editorial website includes personal

observations by Masa Eto on an array of topics,

from world affairs to business. Mr. Eto is the

managing executive officer of the International Division at A&D Company Ltd. |

|

|

| |

|

|

| |

Tom Armstrong of A&D Mercury (ADM) began his presentation by saying, “I would not have done this if I knew all the difficulties we would have had to go through,” when he introduced the new business development project at ADM, which is in conjunction with next year’s business plan at A&D Headquarters (ADC). ADM, our subsidiary in Australia, launched an in-motion check-weighing system of their own design, which they called “Dolphin” six months ago and have already installed four complete units and received a dozen backorders. Tom has reconfirmed on a number of occasions that they are running smoothly and that the customers are perfectly satisfied with their systems. Therefore we knew that when he began his talk about this product developed in Australia, he was extremely proud of the success of this business development idea. This is the first offshoot of the AD-4820, which A&D headquarters introduced utilizing DSP technology in 2003 as part of TNG, The Next Generation, in response to emerging needs in measuring, control and simulation. Tom Armstrong of A&D Mercury (ADM) began his presentation by saying, “I would not have done this if I knew all the difficulties we would have had to go through,” when he introduced the new business development project at ADM, which is in conjunction with next year’s business plan at A&D Headquarters (ADC). ADM, our subsidiary in Australia, launched an in-motion check-weighing system of their own design, which they called “Dolphin” six months ago and have already installed four complete units and received a dozen backorders. Tom has reconfirmed on a number of occasions that they are running smoothly and that the customers are perfectly satisfied with their systems. Therefore we knew that when he began his talk about this product developed in Australia, he was extremely proud of the success of this business development idea. This is the first offshoot of the AD-4820, which A&D headquarters introduced utilizing DSP technology in 2003 as part of TNG, The Next Generation, in response to emerging needs in measuring, control and simulation.

|

|

| |

Tom came to realize that ADM could lose its platform scale manufacturing business because Australia’s competitive edge as a global manufacturing location had weakened in the face of emerging Asian countries. It all started when A&D Korea (ADK) began manufacturing the HV/W-G in the late 1990’s. During its strongest manufacturing period, ADM manufactured as many as 800 platform scales a month for A&D’s global needs. Tom knew that without new business development, the Adelaide factory would be half empty and if manufacturing ceased there, the majority of employees would lose their jobs. Tom came to realize that ADM could lose its platform scale manufacturing business because Australia’s competitive edge as a global manufacturing location had weakened in the face of emerging Asian countries. It all started when A&D Korea (ADK) began manufacturing the HV/W-G in the late 1990’s. During its strongest manufacturing period, ADM manufactured as many as 800 platform scales a month for A&D’s global needs. Tom knew that without new business development, the Adelaide factory would be half empty and if manufacturing ceased there, the majority of employees would lose their jobs. |

|

| |

|

|

| |

An opportunity arose when he met Colin Seddon who had designed various weighing systems using A&D’s controllers and was closely observing new product development at A&D. At that stage, Colin had a total of 26 years experience in weighing and 2 years in the computer industry and this experience in both the weighing systems business and PC-based product development made him reconsider his methods. He says, “When I saw a prototype of the TNG product designed for weighing applications 7 years ago while working at an ADM dealer, I immediately felt that I wanted to be part of this new, exciting business.” For Tom it was a decision to replace a dying business, and for Colin it was a decision to pursue something that he could excel at and also to realize his dream of driving new business. It also meant however that Colin had to give up his position of total control of the global weighing system business he had developed. An opportunity arose when he met Colin Seddon who had designed various weighing systems using A&D’s controllers and was closely observing new product development at A&D. At that stage, Colin had a total of 26 years experience in weighing and 2 years in the computer industry and this experience in both the weighing systems business and PC-based product development made him reconsider his methods. He says, “When I saw a prototype of the TNG product designed for weighing applications 7 years ago while working at an ADM dealer, I immediately felt that I wanted to be part of this new, exciting business.” For Tom it was a decision to replace a dying business, and for Colin it was a decision to pursue something that he could excel at and also to realize his dream of driving new business. It also meant however that Colin had to give up his position of total control of the global weighing system business he had developed.

|

|

| |

|

|

| |

Colin joined ADM in April 2004 and began working on the Linux-run AD-4820 PC-based controller. His original idea was to offer this as an offshoot of ADM’s indicator business to scale dealers who are capable of handling system integration. However, he soon came to realize that this controller which works with Simulink, a MathWorks software development tool, is totally alien to the weighing market even though it is considered to be the most welcome and advanced technology among mechanical engineers involved in cutting-edge measurement, control and simulation. In order to make the product more user-friendly, A&D Headquarters created its own ladder language programming capability (called MC Ladder), which is a de facto standard in the weighing industry and operates with Simulink. However Colin realized that the initial investment in new tools and subsequent training made a lot of weighing dealers hesitant about adopting this new controller. Colin joined ADM in April 2004 and began working on the Linux-run AD-4820 PC-based controller. His original idea was to offer this as an offshoot of ADM’s indicator business to scale dealers who are capable of handling system integration. However, he soon came to realize that this controller which works with Simulink, a MathWorks software development tool, is totally alien to the weighing market even though it is considered to be the most welcome and advanced technology among mechanical engineers involved in cutting-edge measurement, control and simulation. In order to make the product more user-friendly, A&D Headquarters created its own ladder language programming capability (called MC Ladder), which is a de facto standard in the weighing industry and operates with Simulink. However Colin realized that the initial investment in new tools and subsequent training made a lot of weighing dealers hesitant about adopting this new controller. |

|

| |

|

|

| |

Therefore, he decided to explore a different approach, which was to offer a complete solution that would not compete with ADM’s dealers’ businesses. In-motion-check-weighing systems came to his attention, as there are no local Australian manufacturers, except for system integrators, importing key components from abroad. Though he had no experience in this area, it appeared to be fairly simple and straightforward as the AD-4820 is fast enough to process weighing data and flexible enough to be configured for such applications. He figured that it was merely a matter of incorporating an electrical motor to power a moving belt for the weighing base. Therefore, he decided to explore a different approach, which was to offer a complete solution that would not compete with ADM’s dealers’ businesses. In-motion-check-weighing systems came to his attention, as there are no local Australian manufacturers, except for system integrators, importing key components from abroad. Though he had no experience in this area, it appeared to be fairly simple and straightforward as the AD-4820 is fast enough to process weighing data and flexible enough to be configured for such applications. He figured that it was merely a matter of incorporating an electrical motor to power a moving belt for the weighing base.

|

|

| |

|

|

| |

His understanding unfortunately turned out to be premature and naive. In spite of numerous trials he could not achieve accurate measurements with his first prototype as the load cell output regularly fluctuated. He reported this to Satoshi Urata, the AD-4820 Product Manager at ADC and asked him to modify software for digital filtering and averaging which he estimated would reduce these output fluctuations. He faced difficulties in communicating his problems as well as the fact that Mr. Urata was adamant that the problems did not lie with the controller. Out of frustration Colin flew to Japan to speak face-to-face with Mr. Urata so that he could explain the AD-4820 software modifications he needed to suit his applications. His understanding unfortunately turned out to be premature and naive. In spite of numerous trials he could not achieve accurate measurements with his first prototype as the load cell output regularly fluctuated. He reported this to Satoshi Urata, the AD-4820 Product Manager at ADC and asked him to modify software for digital filtering and averaging which he estimated would reduce these output fluctuations. He faced difficulties in communicating his problems as well as the fact that Mr. Urata was adamant that the problems did not lie with the controller. Out of frustration Colin flew to Japan to speak face-to-face with Mr. Urata so that he could explain the AD-4820 software modifications he needed to suit his applications.

|

|

| |

|

|

| |

They met face-to-face and Mr. Urata explained his experiences with Taiwan dealers who also faced the same obstacle with our controllers when they first tried to design their own checkweighers. None of them took account of the fact that a moving or rotating mechanism has a moment of inertia, which constantly changes as the product being weighed moves onto and off the moving belt that sits on the weighing sensors and is therefore a source of considerable disturbance. They discussed different rotators and rotating mechanisms, yet Colin still had difficulties accepting that all of the problems he faced were attributable to his mechanical design, but after lengthy face-to-face discussions and numerous follow-up e-mails he conceded and decided to redesign the mechanical moving parts. The results proved to him that the mechanical designs were in fact the source of his problems. They met face-to-face and Mr. Urata explained his experiences with Taiwan dealers who also faced the same obstacle with our controllers when they first tried to design their own checkweighers. None of them took account of the fact that a moving or rotating mechanism has a moment of inertia, which constantly changes as the product being weighed moves onto and off the moving belt that sits on the weighing sensors and is therefore a source of considerable disturbance. They discussed different rotators and rotating mechanisms, yet Colin still had difficulties accepting that all of the problems he faced were attributable to his mechanical design, but after lengthy face-to-face discussions and numerous follow-up e-mails he conceded and decided to redesign the mechanical moving parts. The results proved to him that the mechanical designs were in fact the source of his problems.

|

|

| |

|

|

| |

|

|

| |

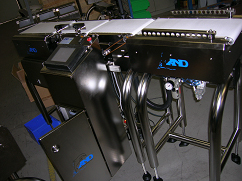

Checkweigher Dolphin with AD-4820 |

|

| |

|

|

| |

Colin says that he had tremendous support from A&D engineers and developed a great rapport with them through continuous communication regarding engineering issues. With one application for a particular customer he had the specifications worked on Monday and by Friday that same week he left Japan with a running product. Five weeks later, 2 sets of AD-4820 checkweighers named “Dolphin” were completed and shipped to the customer. Colin says that he had tremendous support from A&D engineers and developed a great rapport with them through continuous communication regarding engineering issues. With one application for a particular customer he had the specifications worked on Monday and by Friday that same week he left Japan with a running product. Five weeks later, 2 sets of AD-4820 checkweighers named “Dolphin” were completed and shipped to the customer. |

|

| |

|

|

| |

However, a final hurdle appeared unexpectedly. The C-Tick and relevant approval for electronic instruments took longer than forecasted. However, a final hurdle appeared unexpectedly. The C-Tick and relevant approval for electronic instruments took longer than forecasted.

|

| A complete in-motion check weighing system |

This delay cost him two company orders, which ADM secured and then unfortunately had to cancel, which was really demoralizing for his team in charge of this new business development. As a result it took him more than one and half years to get the AD-4820 business up and running. It would not have surprised anyone if he had been so discouraged that he decided to walk away from this venture, but he said to me, “All my life I have had the attitude of never give up. The most important and pleasing factor for me in joining A&D is that the management not only says this, but they also practice it “Never Give UP”. He continued to say, “now that I have an excellent understanding of the products. I can support and sell them in any part of the world. Training and simply time is what is required to use and understand these products.” |

|

| |

|

|

| |

He listed huge advantages for A&D in using the AD-4820: He listed huge advantages for A&D in using the AD-4820:

- ADM can custom-make an AD4820 product to suit any application.

- The AD4820 allows us to target faster checkweigher designs.

- Load cell & I/O Interfaces are already built-in, and with testing and calibration software, this allows faster market distribution.

- Checkweigher multi-channel design for future growth of the Dolphin

- An excellent feature over our competitors is the ability to custom design remote control and data capture using MC Ladder & VirtualConsole (A&D’s original GUI) software.

- While the AD4820 is more sophisticated than the AD4404, the software design makes operation of the AD4820 a lot easier.

|

|

| |

|

|

| |

Tom has not only successfully nurtured new business to fill the gap created by the loss of platform scale production at ADM, but he is also confident that his people are proving A&D’s philosophy of Honmono from within by being relentless till they deliver solutions. It is great to see Honmono in action. Tom has not only successfully nurtured new business to fill the gap created by the loss of platform scale production at ADM, but he is also confident that his people are proving A&D’s philosophy of Honmono from within by being relentless till they deliver solutions. It is great to see Honmono in action.

|

|

| |

|

|

| |

|

|

| |

You may address any comments concerning this editorial by email to Mr. Eto |

|