| AD-4421 |

| High-Speed, High-Precision Weighing Indicator |

|

|

|

|

|

| Features |

Display & Design

|

Clearly Visible LCD Clearly Visible LCD

White-segment LCD with:

Main Display: 8 digits, 14.5 mm character height

Sub Display: 20 digits, 5 mm character height

16-status indicators for real-time status and function display

Compact Panel Mount Design Compact Panel Mount Design

Dimensions: 144 (W) x 72 (H) x 134.7 (D) mm

Panel cutout: 138 x 68 mm

IP65 Front Panel Protection IP65 Front Panel Protection

Ensures dust and water resistance when properly mounted to the control panel

|

|

|

High-speed & High-accuracy Weighing

|

High Performance Digital Filter (HPDF) High Performance Digital Filter (HPDF)

Effectively eliminates vibrations for stable and accurate weighing,

even in harsh environments. Reduces the need for mechanical anti-vibration measures,

cutting costs and maintenance.

High-Speed Sampling High-Speed Sampling

1200 times/second sampling rate enables fast and accurate measurements,

especially when combined with HPDF

Easy HPDF Tuning Easy HPDF Tuning

Use the free WinCT-AD4421 software to visually adjust filter strength and response speed.

|

|

|

Advanced Weighing Functions

|

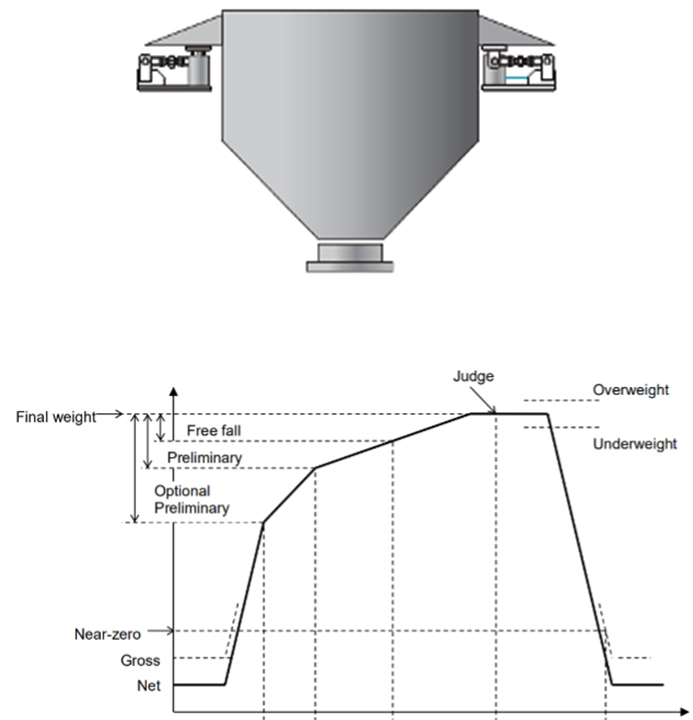

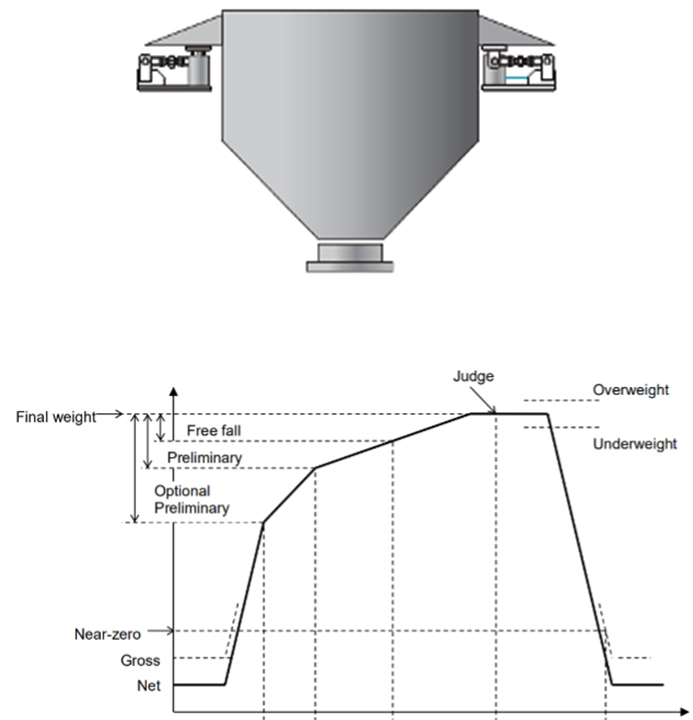

Filling & Dosing Modes Filling & Dosing Modes

Four modes for hopper and packer scales: simple and sequential filling/dosing

Checkweighing Mode Checkweighing Mode

Classifies products by weight using comparator outputs (up to 5 levels)

Automatic Accumulation Automatic Accumulation

Automatically totals net weights; can exclude over/underweight values

100-code Memory 100-code Memory

Stores up to 100 sets of comparison groups (for filling and dosing modes)

and accumulation results

Supplemental Filling Supplemental Filling

Automatically adds small amounts if the target weight is not reached

in filling and dosing modes

|

|

|

Versatile I/O Interfaces

|

Standard Interfaces Standard Interfaces

・ Control I/O: 6 inputs / 8 outputs (open collector, customizable)

・ Serial Output: For A&D printers and remote displays (20 mA current loop)

・ RS-485: For PC communication and command input (Modbus-RTU supported)

・ USB Type-C: For PC connection and data backup via WinCT-AD4421

|

|

|

Optional Interfaces Optional Interfaces

・ BCD Output: Outputs weighing data in BCD format

・ RS-422/485: Additional communication channel (Modbus-RTU supported)

・ RS-232C: For external displays, printers, or PC control

・ Analog Output: 4–20 mA / 0–10 V analog signal output

・ Modbus-TCP: Easy integration with PLCs and HMIs via Ethernet

|

|

|

Ease of Setup & Maintenance

|

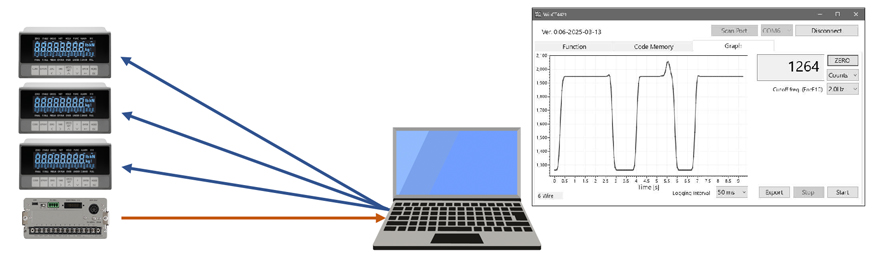

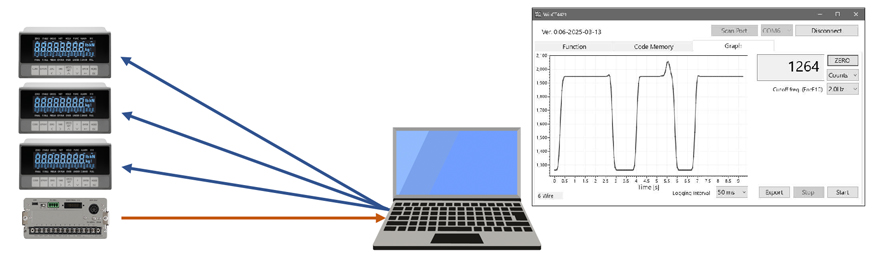

WinCT-AD4421 Software (Free) WinCT-AD4421 Software (Free)

・ Change, back up, and copy internal settings and Code Memory

・ Monitor weighing values and log data to CSV

・ Adjust HPDF settings in real time

・ USB-powered operation for easy setup

|

|

|

4-wire / 6-wire Load Cell Switching 4-wire / 6-wire Load Cell Switching

Software-selectable, eliminating the need for external jumpers

Digital Span Calibration Digital Span Calibration

Enables calibration without actual weights by inputting a reference voltage

|

|

Drawings (PDF) Drawings (PDF)

|

CAD File (DXF)

CAD File (DXF)

|

|

|

|

|