Product

Test and Measurement

- Test Instruments

- Rheometers & Viscometers

- Pipettes

- Noise & Vibration

- Ultrasonic Thickness Gauge

- Specialized Load Cells

- Data Acquisition

- Signal Conditioner

- General Purpose Digital Measurement Equipment

| RPT-3000W | ||||||||||||||||||||||||

| Rigid-body Pendulum Type Physical Properties Testing Instrument | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

| Video | ||||||||||||||||||||||||

| Recommended installation | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

| Vibration Analysis | ||||||||||||||||||||||||

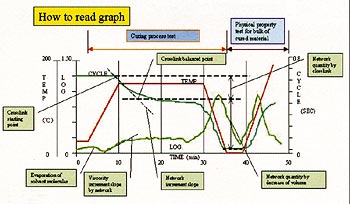

| When the material is cured and dried, the components, which organize the material, increase their molecular weight through a

chemical reaction, called a Chemical Network. The chain molecule moves by thermals and generates a phenomenon called Yarn's Entanglement, and becomes a Physical Network. When fillers, like pigments, are added to the system, the material absorbs the fillers, although absorption depends on the materials. This is called a Physical-Chemical Networks. The effect

appears in the form of a molecular increase. When the material is placed on the base plate, material absorption takes place on the base plate and becomes a Physical-Chemical Network. An increase in molecular weight causes an increase in viscosity, and when it is vibrated in a high viscosity solvent, the amplitude of vibration decrease and makes logarithmic damping ratio greater. Therefore, by evaluating the logarithmic damping ratio, the viscosity change caused by the creation of the network can be measured. With the molecular weight, even if it is due to the same network, the viscosity lowers when the temperature rises, and the logarithmic damping ratio becomes small. When the network is created, the size of the network becomes too small. When the size of the network is greater, the pendulum moves a great distance in order to crush or stretch the network. Therefore, the period of time the pendulum swings increases. However, when the network is created and the size of the network decrease, the distance of the pendulum movement shortens. By measuring the frequency, that is the time of pendulum movement, the size of the network due to the cross linking can be measured. Thus, the curing and drying conditions of the materials can be evaluated by analyzing the logarithmic damping ratio and the change of frequency. |

||||||||||||||||||||||||

| RPT | ||||||||||||||||||||||||

| All materials become a solid state from a liquid state through some action (heat, light, time and others), and produce various physical properties. The change of phase from liquid to solid causes various problems. Due to this fact, there are cases that the expected performance design cannot be achieved and the performance of the material is lowered and changed by some environmental factor in the process. The most important evaluation item among the material evaluations is to pursue the aging change of the chemical-physical performances in the process of curing and drying from a liquid state to a solid state. The instrument developed for this evaluation purpose is a rigid-body pendulum type physical properties testing machine, model RPT-3000W. |

||||||||||||||||||||||||

| Sample of how to read a graph | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

| Available to Evaluate Materials in Versatile Fields | ||||||||||||||||||||||||

| With this instrument, one can evaluate the curing and drying process of organic high polymeric materials, and their bulk physical properties, or evaluate the surface's physical properties and other materials, such as inorganic material like concrete, cosmetics, paper and foods in the operational temperature range from -100 degrees Celsius to 400 degrees Celsius. | ||||||||||||||||||||||||

| -MEASUREMENT- | ||||||||||||||||||||||||

| Fix the test piece coating plate on the cooling/heating block. Set the pendulum so that the knife-edge, the fulcrum of the swing, comes vertically into contact on the test piece coated surface. Apply free vibration to the pendulum. For measurement of physical properties, use a cylindrical edge. By analyzing this vibration, the curing process and surface's physical properties can be evaluated. |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

| EXAMPLES OF TYPEIAL MEASUREMENT | ||||||||||||||||||||||||

| [Curing Behaviors] | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

| Application of RPT - 3000W | ||||||||||||||||||||||||

| This instrument allows measurement of viscoelastic physical properties under a curing process, as well as the surface layer physical properties of the material. Therefore, this instrument is applicable for development/ improvement, quality evaluation, designing and trouble-shooting production line and life evaluation of materials. |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

| Specifications | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

| Specifications subject to change for improvement without notice. | ||||||||||||||||||||||||

| Technical Documentation | ||||||||||||||||||||||||

Paints |

||||||||||||||||||||||||

|

Viscoelasticity Measurement of Coating Film Formation by Free Damping Vibration of a Rigid Pendulum Seiji Ushiama: Viscoelasticity Measurement of Coating Film Formation by Free Damping Vibration of a Rigid Pendulum * This paper is open access, but the copyright belongs to the Japan Society of Color Material. |

||||||||||||||||||||||||

|

Curing Rate Analysis of Coating Film Kanji Mori: Curing Rate Analysis of Coating Film - Rate-determining Process with Catalyst-added MEKO Blocked Isocyanate - Color Material., 89 [5], 145-148 (2016) * This paper is open access, but the copyright belongs to the Japan Society of Coloring Materials. |

||||||||||||||||||||||||

|

Method for Tracking Crosslink Density during Curing Process of a Coating Film Kanji Mori: Method for Estimating Crosslink Density in Curing Process of Coating Films - Proportionality between Storage Modulus and Crosslink Density - Color Material., 86 [4], 123-127 (2013) * This paper is open access, but the copyright belongs to the Japan Society of Coloring Materials. |

||||||||||||||||||||||||

|

Standardization of methods for measuring the physical properties of paints and coatings using a rigid pendulum Atsuo Inoue: Standards Certification Research & Development Business "Standardization of Methods for Measuring Physical Properties of Paints and Coating Films using a Rigid Pendulum" Coating Technology Vol. 55 No.1 p.4-17 (2020) (Copyright belongs to Japan Paint Inspection and Testing Association) (Link to Japanese document) |

||||||||||||||||||||||||

|

Structure and physical properties of inorganic-organic hybrid coating film model Minoru Tsubota, Hiroshi Fukui: "Structure and Physical Properties of Inorganic-Organic Hybrid Coating Film Model" Coating Technology Vol. 55 No.1 p.4-17 (2020) (Only the abstract, the copyright belongs to the Japan Coating Technology Association) (Link to Japanese document) |

||||||||||||||||||||||||

Adhesives |

||||||||||||||||||||||||

| Conduction path development in electrically conductive adhesives composed of an epoxy-based binder | ||||||||||||||||||||||||

| Effect of binder chemistry on the electrical conductivity of air-cured epoxy-based electrically conductive adhesives containing copper | ||||||||||||||||||||||||

| Evolution of Electrical Conductivity in Silver-Loaded Electrically Conductive Adhesives Composed of an Amine-Cured Epoxy-Based Binder | ||||||||||||||||||||||||

| Evaluation of Two-part Epoxy Adhesive using a Rigid Body Pendulum Instrument | ||||||||||||||||||||||||

| Evaluation of Adhesion Between CFRP and SUS Plates Using RPT-3000W Comparison of Adhesives (New and Old, Product Numbers) and Surface Treatments | ||||||||||||||||||||||||

Electrically Conductive Pastes |

||||||||||||||||||||||||

| Tomohito NEGISHI, Masahiro INOUE “Formation of Filler Network Structure and Conduction Path Development in Electrically Conductive Adhesives Containing Silver Flakes” MES2017/8 1E2-3 | ||||||||||||||||||||||||

|

YukariMATSUNAMI,DaisukeOTAJIMA and Masahiro INOUE "Molecular Structure Dependence of Surface Treatment Impact on Electrical Conductivity of Copper-Filled Conductive Paste by Amino Ethanol and Its Derivatives" Journal of Smart Processing, Vol.12,No.5 (2023) |

||||||||||||||||||||||||

|

Subaru Tsujimura and Masahiro Inoue "Effect of Binder Chemistry on Dynamic Percolation in Electrically Conductive Carbon-Nanotube-Filled Pastes during Curing" |

||||||||||||||||||||||||

Polymer Films |

||||||||||||||||||||||||

|

Polymer Inclined Structural Material Saburo Akiyama / Yoshihisa Kano: Inclined Domain Structure Expressed in Polymer Films and Application to New Adhesive Films Polymer, Volume 49, January Issue (2000) Serialization, Recent Advances in Polymer Science (Link to Japanese document) |

||||||||||||||||||||||||

|

Finding the Crystallinity of a Polymer Surface Finding the crystallinity of a polymer surface (Publication of Japanese Patent Application No. 2007-292636A) (Link to Japanese document) |

||||||||||||||||||||||||

|

Measurement example of high polymer film (Link to Japanese document) |

||||||||||||||||||||||||

Cosmetics |

||||||||||||||||||||||||

|

Cosmetics Physical Property Evaluation Method from the October 2012 Issue of Cosmetic Stage "Physical Property Evaluation Method of Cosmetics" (Link to Japanese document) |

||||||||||||||||||||||||

|

Physical characteristics of hair damage (Link to Japanese document) |

||||||||||||||||||||||||

Others |

||||||||||||||||||||||||

|

Introduction of PS Nano Thin Film Measurement We were studying how thin materials could be measured and evaluated using the RPT-3000W. We would like to thank the Tanaka Laboratory of the Department of Applied Chemistry, Graduate School of Engineering, Kyushu University for providing us with a PS thin film sample created on a silicon wafer for measurement. Introduction of PS Nano Thin Film Measurement with RPT-3000W (Link to Japanese document) |

||||||||||||||||||||||||

|

Evaluation of the auxiliary effects of the finish applied by concrete curing agents This is a research report that evaluated the change in viscoelastic behavior of cement paste using a rigid pendulum physical property testing machine using the relative complex elastic modulus. Evaluation of the Auxiliary Effects of the Finish Applied by Concrete Curing Agents * This paper is open access, but the copyright belongs to the Institute of Industrial Science, University of Tokyo. |

||||||||||||||||||||||||

|

Measurement example of copper wire coating (Link to Japanese document) |

||||||||||||||||||||||||

|

What is a rigid pendulum type physical property testing machine? Monthly “Coating Technology" (August 2016 Issue) Technical Report (Link to Japanese document) |

||||||||||||||||||||||||

|

How to read measurement data (curing) (Link to Japanese document) |

||||||||||||||||||||||||

|

How to read measurement data (physical characteristics) (Link to Japanese document) |

||||||||||||||||||||||||

|

||||||||||||||||||||||||